Transformers are critical components in power distribution systems, and their performance directly affects the reliability of electrical networks. To ensure safe operation and prevent unexpected breakdowns, regular transformer equipment maintenance is essential.

This process involves using specialized tools and proven techniques to inspect, test, clean, and repair transformer systems. Understanding these tools and methods helps facility managers and technicians maintain efficiency, reduce downtime, and extend equipment life.

-

Visual inspection tools

Visual inspection is one of the simplest yet most effective steps in maintenance. Technicians use flashlights, binoculars, thermal camera viewers, and inspection mirrors to check for oil leaks, corrosion, cracks, and loose connections.

These tools allow quick identification of physical issues that could lead to serious failures if ignored. Visual inspection also includes checking insulation conditions and physical damage to external parts.

-

Infrared thermography

Infrared cameras play a crucial role in detecting abnormal heat patterns in transformer components as part of effective transformer equipment maintenance. Hot spots can indicate loose connections, overloaded circuits, or failing insulation, all of which are common issues addressed through proper transformer equipment maintenance.

Thermographic imaging allows technicians to inspect equipment without shutting it down, making it a preferred technique for early fault detection. This method helps prevent overheating-related failures.

-

Oil testing equipment

Transformer oil serves as both an insulator and a coolant, so its condition is critical. Oil testing tools measure moisture content, acidity levels, dielectric strength, and dissolved gases. Common tests include dissolved gas analysis (DGA) and breakdown voltage tests.

These tests help identify internal faults such as overheating or electrical arcing long before physical damage becomes visible.

-

Electrical testing instruments

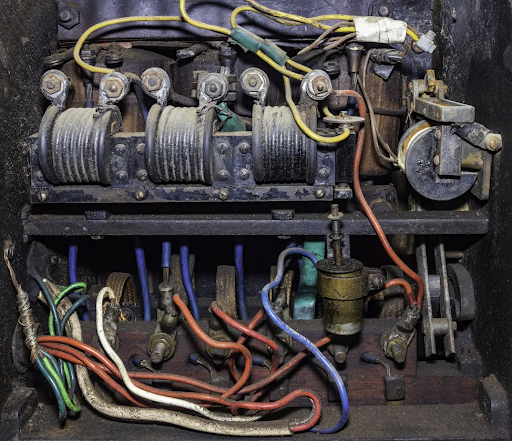

Electrical testing equipment such as insulation resistance testers, winding resistance meters, and turns ratio testers are widely used to ensure proper operation. These tools evaluate the condition of internal windings and connections.

Abnormal readings can signal insulation breakdown, short circuits, or mechanical damage. Regular electrical testing ensures transformers continue operating within safe limits.

-

Cleaning and filtration systems

Dust, dirt, and moisture can negatively impact transformer performance. Cleaning tools such as industrial vacuums, dry air blowers, and soft brushes are used to remove contamination from internal and external parts.

Oil filtration machines remove moisture and impurities from transformer oil, restoring its insulating properties. These systems help extend oil life and improve cooling performance.

-

Vibration and sound analysis

Transformers produce specific sound and vibration patterns during normal operation. Specialized sensors and analyzers detect unusual noises or vibrations that may indicate loose components or internal malfunctions.

This technique is especially useful in identifying mechanical faults that are difficult to detect through visual or electrical inspections alone.

Conclusion

Transformers operate under demanding conditions, making regular inspections and testing essential. The tools and techniques described above form the foundation of effective transformer equipment maintenance. By combining visual inspections, diagnostic testing, oil analysis, and modern monitoring tools, organizations can prevent unexpected failures and optimize performance. Proper maintenance not only protects expensive equipment but also ensures uninterrupted power supply and improved system reliability. Investing in the right tools and following proven techniques creates safer working environments and significantly reduces repair costs over time.